royex quarry concept

Break and pull

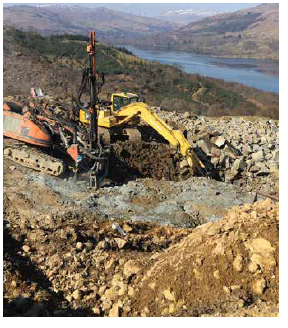

Royex break and pull concept

For quarries with challenges in using conventional explosives, the Royex break and pull concept could mean a drastic increase in productivity. As the Royex cartridge is non an high explosive and is significantly less intrusive, the system can be used in operations where high explosive use is forbidden or difficult to use.

- Break

By drilling aggressive patterns, and charging with a suitable Royex cartridge, in-situ rock can be split and moved into bigger pieces.

The Royex system is very effective at this and can produce large amounts of blocked rock per hole. A typical drill pattern for a Royex break pattern is:

Drill diameter: 48 mm

Burden: 2 m

Spacing: 2,4 m

Drill depth: 3,2 m

Volume per hole: 15,36 m³

Various alternations of this pattern could be required for optimal performance and is strongly dependent on geology, rock competence, hardness and density.

As can be seen, impressive amount of rock may be split from an in-situ face using only one Royex cartridge per hole.

- Pull

The bigger blocks produced by the Royex system will be split from

the rock face but they will not be thrown or fragmented like with

conventional explosives.

Hence, the rock have to be pulled from the face and broken with

hammers or crushers into the required size. The process of using Royex to split the rock from a solid in-situ structure has a great impact on performance.

A productivity comparison from a real operation is;

Using only hydraulic hammers for rock production:

3 x 50 ton machines with 4 ton hammers 600 tonnes produced per

day due to in situ removal time.

Using Royex break and pull:

One drill and break crew and 2 x 50 tonne machines with 4 ton

hammers. 40 holes drilled and fired per day @ 15 m³ per hole. Density 2,6 ton / m³ gives a total of 1560 tones per day.

260% production increase with significant economic saving

A video example of the Royex Break and Pull concept for a quarry operation can be found below.