The Royex cartridge is a non-detonating rock breaking cartridge. It is classified as a pyrotechnic article and holds a 1.4S transport classification. In the European Union, the cartridge is classified as a P2 product, under the European directive for pyrotechnical articles, by the BAM laboratory in Berlin, Germany.

The cartridge consists of a plastic housing containing a pyrotechnic propellant mixture. The robust plastic housing is designed to protect the propellant mixture and the igniter during handling and charging. Royex cartridges are currently offered in three diameters: 22, 32 and 38 mm in lengths from 70 mm to 1100 mm.

The 22 mm cartridge has been specially designed for very precise pre-splits where fracture zones must be eliminated and wall integrity is paramount. Typical applications are dimensional stone breaking in slate, limestone, granite, marble and similar rock types. or for tunnel perimeter blasting. The 22 mm cartridges are also ideal for concrete demolition or in areas where only small diameter drilling equipment is available.

Royex 32 mm cartridges are the product of choice for highly sensitive civil projects. Containing enough breaking power to be cost efficient, the 32 mm cartridge maintains an excellent vibration control and fly rock minimization. Typical applications include precision civil projects such as bench blasting in urban environments or indoors. Trenching, wells or tunnel development applications are also situations where the 32 mm cartridges has multiple uses.

A Royex 38 mm cartridge is ideal for tunnel development or surface developments where larger burdens and hole depths can be allowed. It is also suitable for bigger operations where small hole drilling capabilities are scares or unavailable.

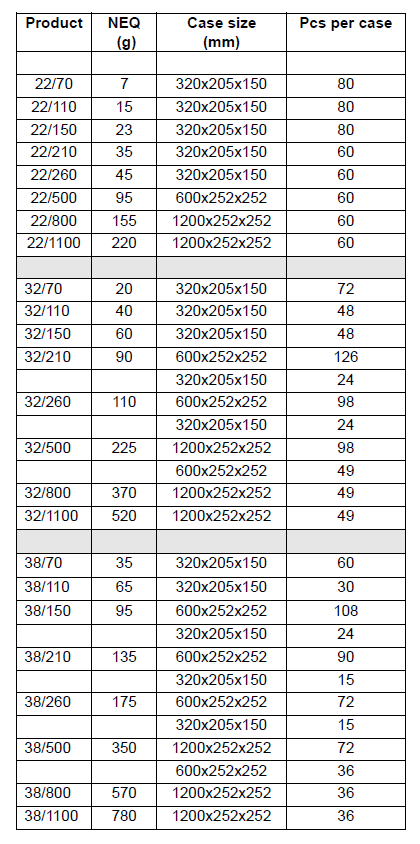

AVAILABLE SIZES

The article names for the Royex cartridge product line are denoted <diameter> / <length>

in millimeter, NEQ is noted separately.